THK World Standard HSR Linear Guide Unveiled!

Publish Time:

2025-03-10

THK Linear Guide HSR Unveiled

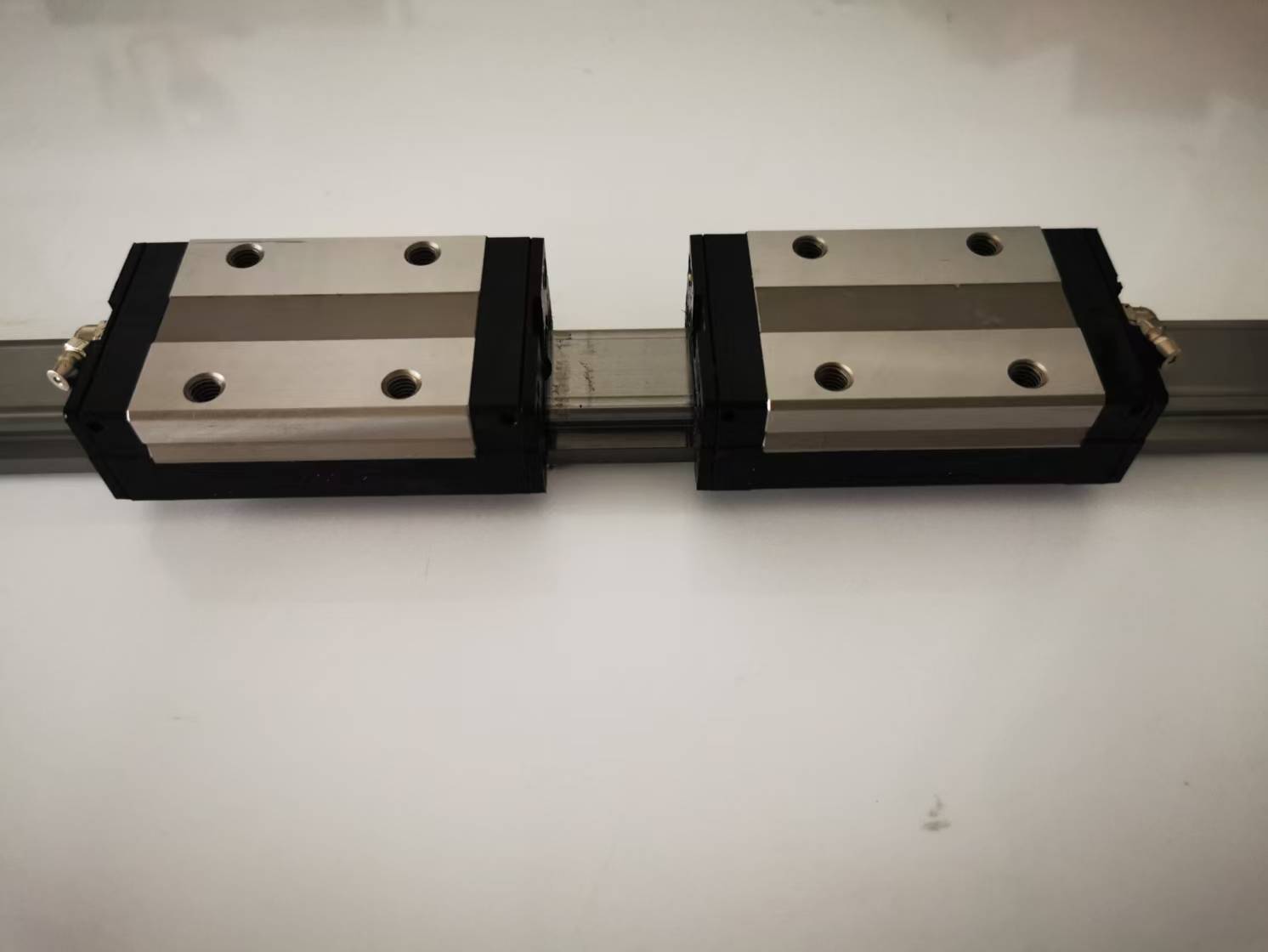

In the field of mechanical manufacturing, linear guides serve as crucial components, playing a pivotal role in the accuracy, stability, and efficiency of equipment. THK, an industry leader, has garnered significant attention for its HSR linear guides due to their exceptional performance and wide-ranging applications. This article delves into the THK HSR series linear guides, revealing their inner workings.

I. HSR Series Characteristics

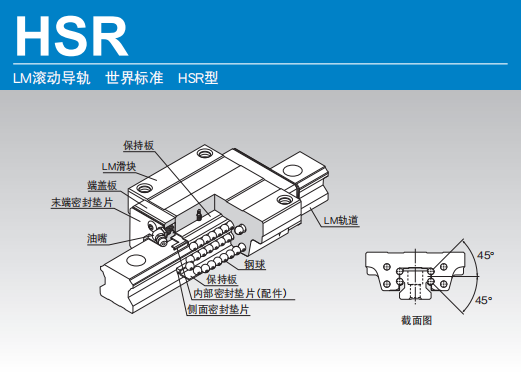

1. High Load and High Precision: HSR linear guides are used in linear reciprocating motion applications. They boast a higher rated load compared to linear bearings, while also handling a degree of torque. They enable high-precision linear motion under high loads. Their unique four-row rolling element design, with each steel ball row configured at a 45° contact angle, allows the slide block to withstand the same rated load in four directions—radial, anti-radial, and lateral—ensuring stable operation regardless of mounting orientation and maintaining high-precision operation in complex conditions.

2. Low Friction and High Speed: With precisely ground rolling surfaces and the recirculating motion of the steel balls, HSR linear guides maintain a low coefficient of friction. This not only reduces energy loss but also enables high-speed motion, improving equipment efficiency. They are suitable for applications with high-speed requirements, such as high-speed machine tools and automated production lines.

3. High Rigidity and Stability: HSR linear guides feature a high-rigidity slide block design and evenly applied preload, enhancing rigidity in all four directions. This ensures stability and prevents deformation under heavy loads and high-speed motion, guaranteeing normal equipment operation and machining accuracy. They are often used in large-scale machinery and heavy-duty applications.

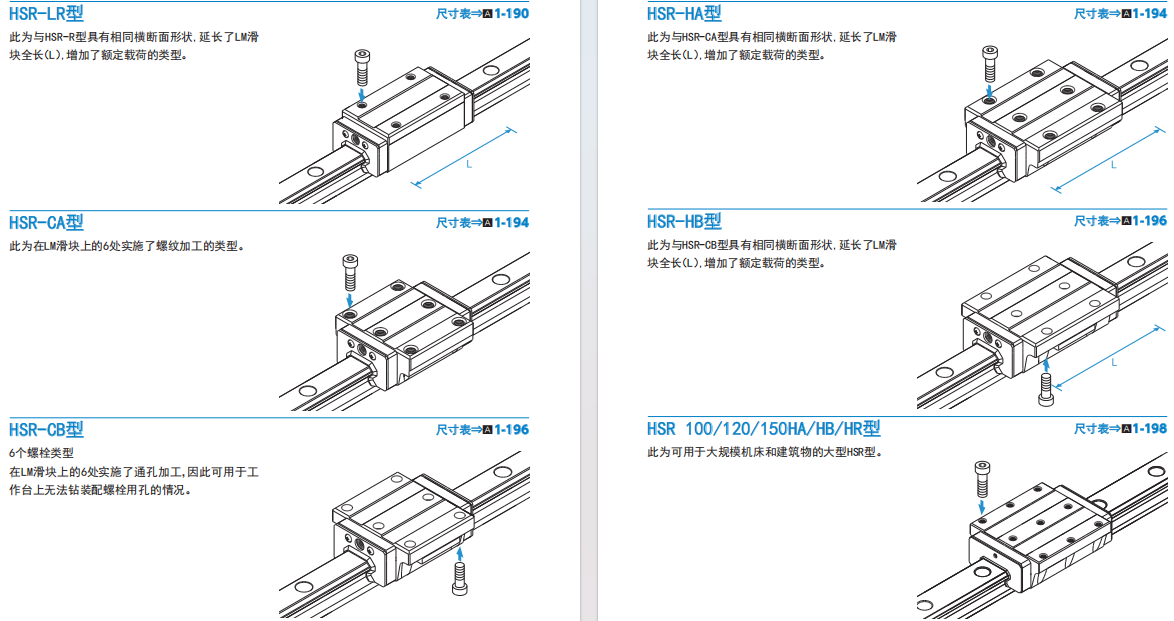

II. Model Classification and Applications

The HSR series includes various models, such as HSR15, HSR20, HSR25, HSR30, HSR45, HSR55, HSR65, and HSR85. Different models vary in size and load capacity to meet the needs of different equipment.

1. Small Equipment: Smaller models like HSR15 and HSR20 are suitable for light-duty machinery with lower load and higher precision requirements, such as small CNC machine tools and electronic equipment manufacturing equipment. Their compact size meets stringent space requirements, while their high precision enhances machining accuracy.

2. Medium-sized Equipment: Models such as HSR25 and HSR30 can handle medium loads and are often used in linear motion components of general machine tools and industrial robots. Their rational structural design and material selection ensure stable performance under medium loads, effectively extending equipment lifespan.

3. Large Equipment: Larger models with higher load capacities, such as HSR45, HSR55, HSR65, and HSR85, are suitable for large processing equipment, heavy machinery, large presses, injection molding machines, ultra-large machinery, and large gantry milling machines where high load-bearing capacity is required. In these large-scale equipment, the HSR series slide blocks can withstand significant cutting forces, impact forces, and loads, ensuring precise linear motion of the equipment's worktable and guaranteeing stability and reliability.

The HSR series is widely used in woodworking machinery, CNC machining centers, grinding machines, printing and packaging equipment, semiconductor manufacturing equipment, and precision measuring instruments. In CNC machining centers, HSR linear guides ensure precise tool movement, improving machining accuracy and surface quality. In printing and packaging equipment, they ensure smooth movement of printheads, packaging robotic arms, and other components, improving printing and packaging accuracy and speed.

III. Special Environment Models

Based on the HSR product specifications, THK has developed various "special environment LM guides" suitable for use in special environments.

1. HSR - M1: High-temperature LM guides with a maximum operating temperature of 150°C, meeting the needs of equipment operating in high-temperature environments, such as some heat treatment equipment and high-temperature testing equipment.

2. HSR - M2: Made of highly corrosion-resistant stainless steel, exhibiting excellent corrosion resistance. Suitable for corrosive environments such as chemical equipment and food processing equipment (where exposure to corrosive cleaning agents may occur).

3. HSR - M3: Low-permeability LM guides resistant to magnetic fields. Using low-permeability materials in both the LM rail and LM slide block, this product maintains performance in magnetic field environments. It remains unaffected by magnetic fields, even in environments with strong magnetic fields, such as MRI equipment and various testing equipment, ensuring smooth movement.

IV. Selection Points

1. Load Size and Direction: Select the appropriate HSR linear guide model based on the size and direction of the load borne by the slide block during equipment operation. Ensure that the rated load meets requirements and stable load-bearing is possible in all directions.

2. Precision Requirements: HSR linear guide precision grades are classified into standard grade (unmarked), (H), precision grade (P), super-precision grade (SP), and ultra-super precision grade (UP). Choose the appropriate precision grade based on the equipment's motion precision requirements. High-precision grade guides are typically needed for precision measuring instruments and semiconductor manufacturing equipment.

3. Speed Requirements: Consider the operating speed of the equipment. While the HSR series can adapt to higher speeds, different models have varying speed performance. For high-speed equipment, select a model more suitable for high speeds.

4. Installation Space: Considering the equipment's installation space, choose a guide model of appropriate size. Ensure smooth installation and that the guide doesn't interfere with other components.

5. Environmental Factors: If the equipment operates in special environments with high temperatures, corrosion, or magnetic fields, prioritize the corresponding special environment models, such as HSR - M1, HSR - M2, and HSR - M3.

Thank you, high-speed rail, linear guide rail, load, precision

Latest News

Get a Free Consultancy

No. 39, Life Second Road, Dalian Economic and Technological Development Zone, 8-5

Copyright © 2025 Maoming Precision Machinery (Dalian) Co., Ltd. All Rights Reserved.

2025-01-08

2025-01-08