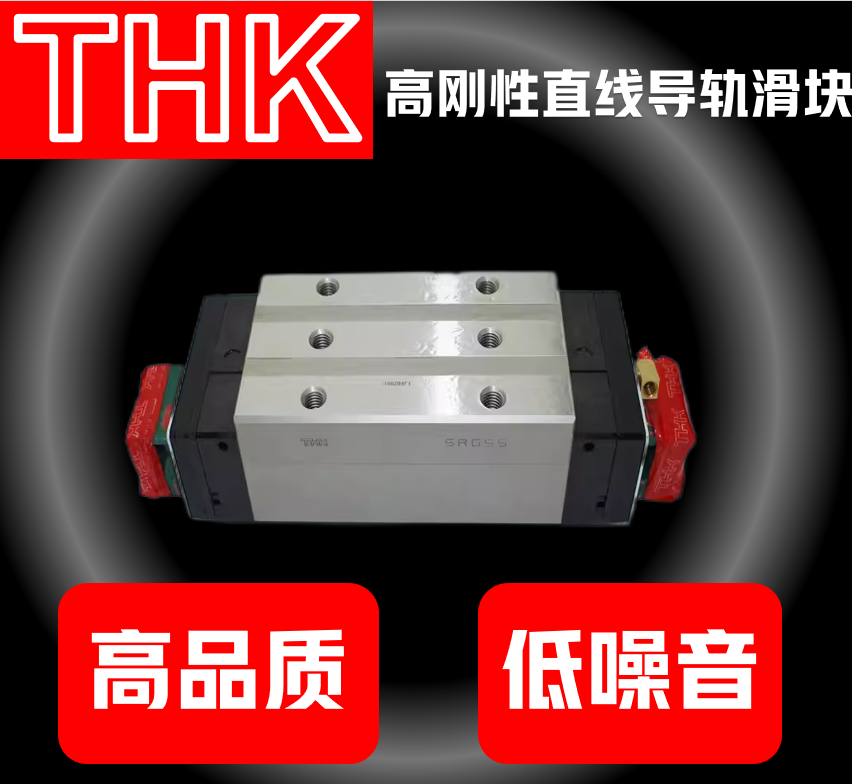

Japanese imported THK linear guide SRG series makes equipment run as fast as lightning

Publish Time:

2025-03-14

THK SRG Series Linear Guide: Innovative Power for Industrial Backbones

In the tide of intelligent manufacturing, THK's SRG series linear guide redefines the standards for heavy-duty precision transmission with its groundbreaking roller retainer technology, providing high-end equipment with a core solution that combines high rigidity, low friction, and long life. As a benchmark product in the field of roller guides, the SRG series, through material innovation and structural optimization, is reshaping the future of industrial transmission.

I. Core Technological Breakthrough: The Perfect Balance of Heavy Load and Precision

This series of linear guides boasts a robust structural design. By optimizing the track shape and roller arrangement, it significantly improves the rigidity and load-carrying capacity of the linear guide. It can easily handle high-load conditions, ensuring stable operation even when the equipment is subjected to significant external forces. In the field of machine tool processing, the SRG series linear guide can support heavy cutting tools and workpieces, maintaining stability during high-speed cutting to ensure processing accuracy and surface quality, thus improving production efficiency.

Application Case: TRUMPF Laser Cutting Machine After equipping the TRUMPF TruLaser 5030 machine tool with SRG 85 guides, the dynamic positioning accuracy remained stable at ±0.008 mm during high-speed cutting of 6 mm stainless steel plates, and processing efficiency increased by 30%. Its roller retainer technology effectively absorbs cutting vibrations, avoiding the edge chipping problems caused by insufficient rigidity in traditional ball guides.

II. Long-lasting Performance: The Arrival of the Maintenance-Free Era

The SRG series linear guides use high-quality materials and special surface treatment processes, giving them excellent wear resistance. During long-term continuous operation, the wear on the guide surface is minimal, effectively extending the equipment's maintenance cycle and service life. Even under high-intensity work conditions in automated production lines, the SRG series linear guides maintain good performance, reducing equipment downtime and lowering operating costs for businesses.

Application Case: Tesla Shanghai Gigafactory Stamping Line

The stamping production line at Tesla's Shanghai factory uses SRG-L extended guides. Under high-intensity conditions with 24-hour continuous operation, the lubrication cycle is extended to 4500 hours, reducing downtime maintenance by 70% compared to traditional guides. Special surface treatment technology extends the guide life beyond 30,000 hours, reducing maintenance costs by 40%.

III. Application Scenarios: Core Support for High-end Manufacturing

1. Machine Tool Processing Field

The Yamazaki Mazak INTEGREX i-400 AM hybrid machine tool uses SRG 65 guides to maintain micron-level accuracy during 5-axis linkage processing. Its 45° contact angle design allows the machine tool to withstand an overturning moment of 800 N·m, ensuring the stability of complex surface processing.

2. Industrial Robots

After adopting SRG modular guides, the load capacity of the KUKA KR 1000 Titan heavy-duty robot increased from 800 kg to 1000 kg, with repeat positioning accuracy reaching ±0.005 mm. In automotive body welding, the cycle time was shortened by 15%, and the weld consistency improved by 25%.

3. Semiconductor Manufacturing

The wafer handling system of TSMC's 3nm chip production line uses customized SRG-Nano guides to achieve nanometer-level positioning in a cleanroom environment. Its hooded roller technology prevents 0.1μm particles from entering, ensuring that the equipment's annual fault-free operating time exceeds 8700 hours.

4. Medical Imaging Equipment

The Siemens SOMATOM Force CT scanner uses SRG silent guides to control vibration noise during scanning to below 55 decibels. The low-friction characteristics increase the gantry rotation speed to 0.25 seconds/revolution while maintaining sub-millimeter slice thickness accuracy.

IV. Innovation and Upgrades: The Future of Intelligent Transmission

The SRG series linear guides use THK's unique advanced manufacturing processes and precision grinding technology to ensure that the matching accuracy of the guide and slider reaches the micron level. This high-precision characteristic allows the equipment to achieve extremely precise positioning and movement during operation, effectively avoiding product quality problems caused by errors. In semiconductor manufacturing equipment, the SRG series linear guides can precisely control the handling and processing position of wafers, meeting the requirements of nanometer-level manufacturing processes, providing strong hardware support for the development of the semiconductor industry.

Application Case: Boston Dynamics Robot

Boston Dynamics' Spot Mini robot integrates lightweight SRG guides in its joint transmission, increasing the payload-to-self-weight ratio by 40%. Integrated displacement sensors monitor the joint status in real-time, predicting potential failures through AI algorithms and improving maintenance efficiency by 60%.

V. Industry Benchmark Application Examples

From precision machine tools to automated production lines, from medical equipment to semiconductor manufacturing, THK SRG linear guides, with their revolutionary technological breakthroughs, are driving global industrial equipment towards higher precision and higher efficiency. Choosing the SRG series is not just choosing a transmission component, but also choosing the core competitiveness of the intelligent manufacturing era.

If you have any objections or needs, please feel free to contact me, and welcome everyone to discuss together. Contact number: 15524757549 (WeChat synchronized)

srg, guide rail, linear guide rail, manufacturing, precision, machine tool, maintenance

Latest News

Get a Free Consultancy

No. 39, Life Second Road, Dalian Economic and Technological Development Zone, 8-5

Copyright © 2025 Maoming Precision Machinery (Dalian) Co., Ltd. All Rights Reserved.

2025-01-08

2025-01-08