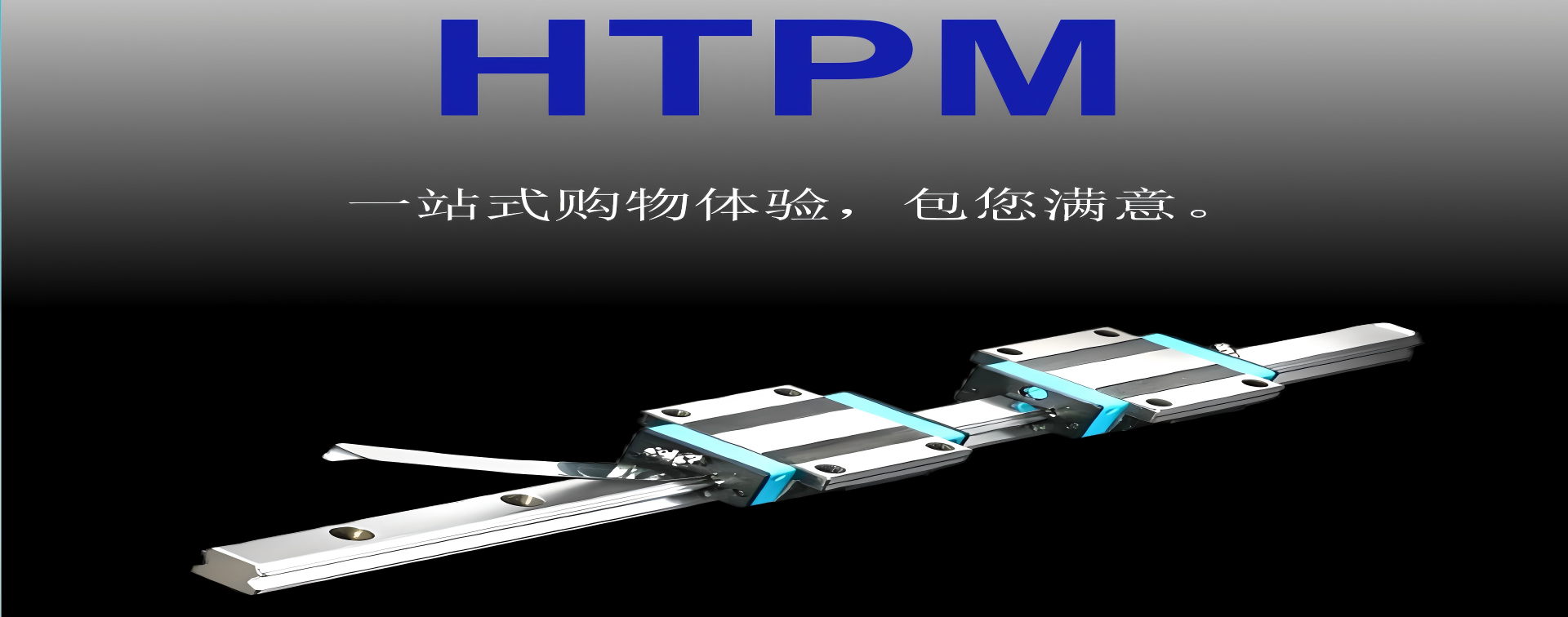

Kate LGS Linear Guide Rail Unveiled

Publish Time:

2025-02-27

Kate LGS Linear Guide: A Shining Star in the Field of Precision Transmission

In the vast world of industrial automation and precision machinery, linear guides, as core components for achieving precise linear motion, directly affect the overall performance of equipment. Kate LGS linear guides, with their outstanding achievements in design, process, and performance, have become the preferred choice of numerous high-end equipment manufacturers, providing a solid guarantee for the efficient and stable operation of various precision equipment.

I. Innovative Design, Precisely Adapting to Diverse Needs

The Kate LGS linear guide features a unique design philosophy, fully considering the complex working conditions in different application scenarios. Its Gothic arc groove design, compared to traditional designs, allows the steel balls to form a four-point contact with the groove. This ingenious structure greatly improves the guide's ability to withstand loads from multiple directions. Whether it's vertical pressure, horizontal thrust, or lateral impact, the LGS linear guide ensures the stability and precision of equipment operation through its unique design, laying a solid foundation for stable equipment operation.

The cooperation between the slider and the guide is ingenious. After repeated optimization, the gap between the two is precisely controlled, which not only effectively reduces frictional resistance during movement, improves transmission efficiency, but also significantly reduces noise and vibration during operation. This near-perfect match is of great significance to industries with strict environmental requirements such as optical instruments and medical equipment, creating a quiet and stable operating environment for the equipment and ensuring the smooth progress of precision operations.

II. Exquisite Craftsmanship, Strict Standards Create Excellent Quality

In manufacturing LGS linear guides, Kate strictly follows the international leading quality control system. Starting from the selection of raw materials, high standards are followed, selecting high-quality alloy steel as the basic material. These raw materials undergo special heat treatment processes, with uniform and extremely high surface hardness, giving the guide excellent wear resistance and fatigue resistance, fundamentally extending the product's service life.

In the precision machining stage, Kate relies on advanced CNC machining equipment and precision testing instruments to strictly control the dimensional accuracy of the guide and slider. Key indicators such as the straightness and flatness of the guide and the parallelism of the slider are precisely controlled within the micrometer range. Before leaving the factory, each set of LGS linear guides undergoes multiple rounds of rigorous quality inspection procedures. Only products that fully meet high-standard quality requirements are eligible to enter the market, ensuring that every set of guides users receive has excellent quality.

III. Excellent Performance, Leading the Industry Development Track

Strong load carrying capacity: The perfect combination of unique structural design and high-quality materials gives the LGS linear guide a strong load carrying capacity. Under the same size specifications, its load carrying capacity far exceeds similar products, sufficient to cope with application scenarios with stringent requirements for high load capacity, such as large-scale machinery and heavy-duty automated production lines, providing strong support for efficient equipment operation.

Ultra-high precision positioning: Micrometer-level precision ensures that the LGS linear guide can achieve extremely precise positioning operations during equipment operation. Whether it's precise tool feeding for precision machine tools, precise wafer handling for semiconductor manufacturing equipment, or precise measurement tasks for automated testing equipment, the LGS linear guide can accurately deliver moving parts to the designated position, providing reliable guarantees for improving product processing precision and production efficiency, helping enterprises stand out in fierce market competition.

High-speed and efficient operation: The optimized design with low frictional resistance allows the LGS linear guide to easily achieve high-speed and high-acceleration operation. In fields with extremely high requirements for operating speed and response speed, such as automated logistics equipment and high-speed sorting systems, the LGS linear guide can quickly respond to equipment start and stop commands, completing material transportation and sorting tasks at extremely high speeds, significantly improving the overall operating efficiency of the logistics system and reducing operating costs.

Extra-long service life and convenient maintenance: High-quality materials and exquisite craftsmanship give the LGS linear guide excellent wear resistance and fatigue resistance, ensuring that it can maintain stable performance even under long-term high-intensity operation. At the same time, the guide is equipped with an advanced automatic lubrication system, which can continuously provide sufficient lubrication for key components, reducing manual maintenance workload and frequency, reducing equipment maintenance costs, and improving the convenience and reliability of equipment use.

IV. Wide Application, Deeply Empowering the Development of Multiple Industries

With its excellent performance, Kate LGS linear guides have demonstrated strong empowerment in multiple industries. In the field of machine tool manufacturing, it provides high-precision linear motion guarantees for various precision machine tools, helping to process parts to higher dimensional accuracy and surface quality standards; in the electronics manufacturing industry, LGS linear guides help semiconductor equipment and electronic assembly equipment achieve high-speed and precise motion control, meeting the production needs of electronic products continuously moving towards miniaturization and refinement; in the medical equipment field, its high precision and low noise characteristics enable medical imaging equipment and surgical robots to provide more precise diagnostic and treatment services for patients; in the field of automated logistics and warehousing, LGS linear guides help automated sorting equipment and stacking machines operate efficiently, promoting the development of logistics and warehousing systems towards intelligence and efficiency.

With innovative design, exquisite craftsmanship, excellent performance, and wide applicability, Kate LGS linear guides have become a well-deserved leader in the field of precision transmission. It not only provides strong support for equipment upgrades and technological innovation in various industries, but also promotes the entire manufacturing industry towards high precision, high efficiency, and intelligence. Choosing Kate LGS linear guides means choosing a precise, efficient, and reliable linear motion solution, injecting strong impetus into the sustained development of enterprises.

If you have different opinions, please leave a message. Business owners and leaders who need guides, sliders, or ball screws can also contact me at any time. Contact number: 15524757549

Kate, linear guide rail, lgs, precision, accurate, guide rail

Latest News

Get a Free Consultancy

No. 39, Life Second Road, Dalian Economic and Technological Development Zone, 8-5

Copyright © 2025 Maoming Precision Machinery (Dalian) Co., Ltd. All Rights Reserved.

2025-01-08

2025-01-08